Ito Electrode Cleaning

TiO2 blocking layer electrode Clear TiO 2 FTO layers as starting electrodes of for dye and perovskite solar cells In many types of solar cells the first layer is a blocking layer which thoroughly covers the FTO substrate. Wash with dilute detergent 1 VV and rinse with deionized water.

A Overall View Of A Mesh Patterned Ito Electrode Design Of B Download Scientific Diagram

Im trying to cleaning ITO electrodes 8-12 Ohms with differents pre-treatments.

Ito electrode cleaning. Do not clean in ozone cleaner. To minimize the accumulation of material cleaning immediately following electroporation is recommended as per the Maintenance section of the Instruction Manual summarized below. How I can clean ITO electrodes.

Only the standard ITO electrode cleaning procedure is used. PSS aqueous solution was filtered through a 045 m filter and spin-coated at 2000 rpm for 60 s on the ITO electrode in air. For wavelength above 350 nm the transmittance is above 90.

We start with electroformation using a pair of ITO-coated coverslips which had previously been used three times for Corresponding author. ITO is swabbed under a diluted detergent eg. Measurements obtained with this novel method were compared with measurements obtained using conventional electrochemical immunosensors in which the surface where the immune reaction occurs is not separated from the electrodes.

Organic cleaning had negligible effect on the reduction of the contact resistance but alkali cleaning. 6222012 The pre-cleaned ITO substrate was treated in an ultravioletozone chamber Ultraviolet Ozone Cleaner Jelight Company USA for 20 min. 9112020 This division was accomplished using streptavidin-coated MPs with a clean ITO electrode.

A thin layer of TiO 2 is the most commonly used blocking layer and the films are best deposited by spray pyrolysis. Iii ITO AD exposed to UV light for 30 min under ambient conditions ITO UV. I the as-deposited ITO on a Si wafer ITO AD.

The transmittance is about 10 at 250 nm of the wavelength. Do not scratch the electrode surface to avoid the pattern area conductivity break down. H 2O 2 30 aqueous solution 41 Piranha etch at 80 C for 10 s.

Clean with 70 ethanol or isopropanol. Subsequently the PEDOT. For ITO electrode the light cannot be transmitted easily in ultraviolet range.

Iv ITO AD exposed to ozone for 30 min under ambient conditions ITO ozone. The transmittance of the Indium Tin Oxide ITO glass coverslips at 550nm are greater than 85. Self-assembled monolayer SAM modified ITO surface was also tried.

1212007 ITO indiumtin oxide surface was wet cleaned with organic solvent or alkali solution. Do not immerse the electrode in an organic solvent for long time to avoid peeling of the electrode pattern and passivation membrane. Ii ITO AD rinsed with an organic solvent pure ethanol to dissolve and remove adventitious organic contaminants adsorbed on the surface ITO EtOH.

A Sonicate 10 min EtOH sonicate 10 min MQ water. A Sonicate 10 min EtOH sonicate 10 min MQ water. The electrode was dried by a purified nitrogen stream.

It is also known as ITO wafer. C Wash in flowing DI water for 3 min. 7151998 We therefore assume that the ITO elec- trode has to be cleaned as well as possible and display a high work function in order to enhance the LED performance.

Deconex or FPD detergent Alconox. However an optimized ITO surface cleaning procedure for polymer LED fabrication has not been established yet. 2122018 The proposed patterned ITO electrodes were simply fabricated by photolithography and wet etching.

Activation of Platinum A procedure for producing surface oxide believed to be a monolayer with available surface hydroxyls. PSS film was baked at 150 C for 10 min in air. The LDH-modified electrodes were prepared by casting 20 μL of the LDHs suspension on the surface of clean ITO electrodes.

11302019 Six different ITO surfaces were prepared using different surface cleaning methods Figure 1a. The fabrication of planar heterojunction p-i-n perovskite solar cells started with cleaning ITO coated glass substrates sequentially with mild soap solution deionized water acetone and isopropanol in an ultrasonic bath for 15 minutes in each step. B Immerse in 41 conc.

The LDH nanoparticles were dispersed into water 10 mgmL 1 and sonicated for 20 min to form a homogeneous suspension. Rinse electrode contact area in warm water. A Clean the electrode using an appropriate solvent cleaning procedure above.

If you want to clean the electrode with organic solvent only rinse with acetone or ethanol. Im trying to cleaning ITO electrodes 8-12 Ohms with differents pre-treatments. Soaked under the detergent at 60C for 10 min.

Cleaned substrates were then dried in the fast flow of dry nitrogen gas followed by UV-. 7282017 ITO electrodes were used as substrates and first cleaned by sequential sonication in acetone ethanol and H 2 O for 20 min each. Soap 10 Water 10 Isopropanol 10 I am also using different combinations of each pre-treatments.

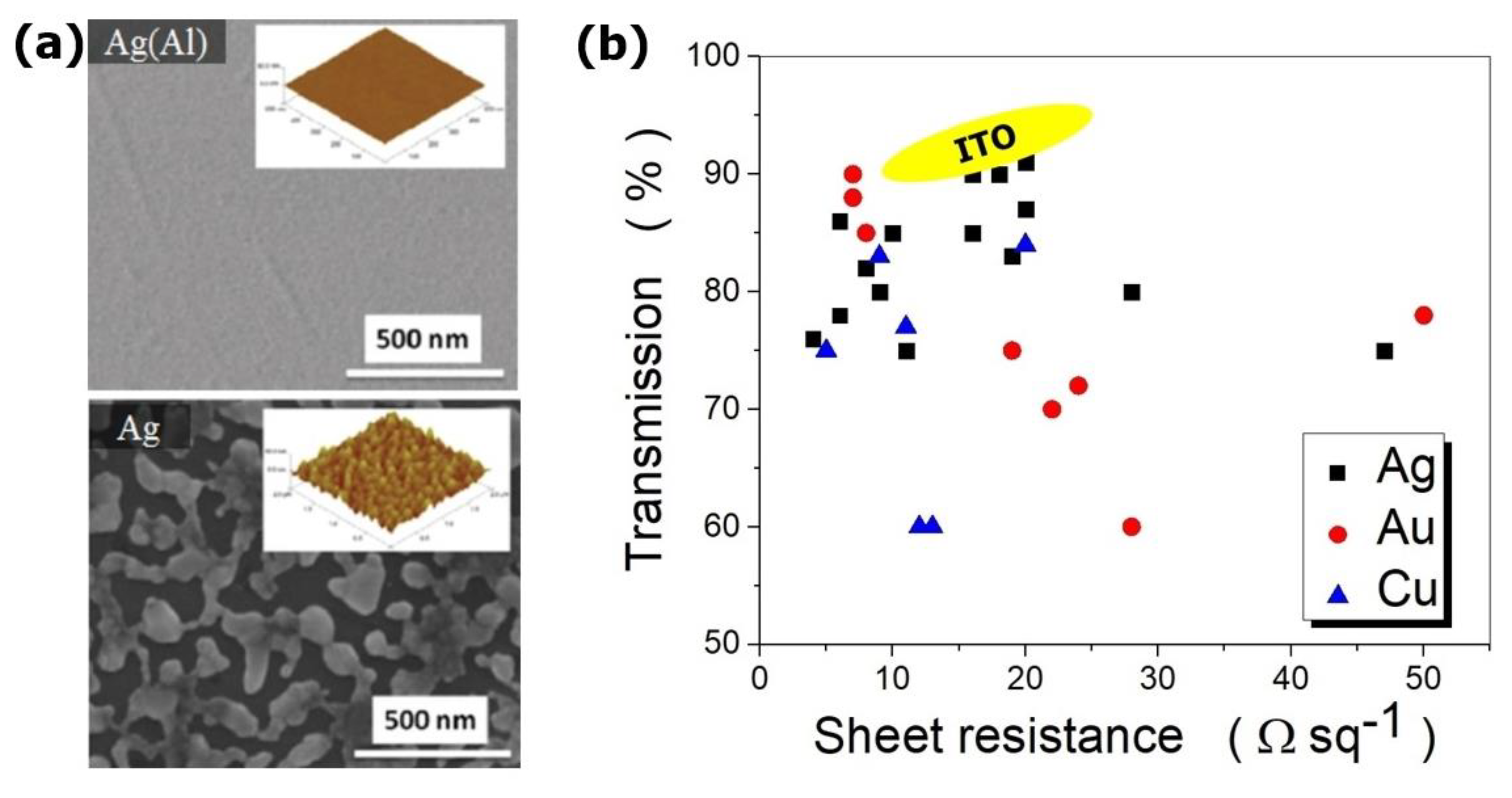

The light transmittance was compared with ITO electrode and Grid electrode Au Pt and Carbon on a quartz glass as a reference. 112016 Our ITO glass supplier Xinyan Technology wwwxinyanhk suggest the below cleaning procedures. The surface roughness is 1-10 nm depending on their specifications whereas the ITO work function is 4849eV after a proper cleaning.

The ITO film or layer thickness is in the range of 50nm to 200nm ie. EtOH 10 Acetone 10 and Isopropanol 10 C Sonicate in.

The Edx Results Of Prepared Ito Thin Film Download Scientific Diagram

Concept Of Highly Bendable Transparent Mesh Patterned Ito Electrodes Download Scientific Diagram

C Free Full Text Carbon Allotropes As Ito Electrode Replacement Materials In Liquid Crystal Devices

Transmission Spectra Of Fto And Ito Coated Glass With Respect To The Download Scientific Diagram

Ito Obtained By Spray Pyrolysis And Coating On Glass Substrate

Komentar

Posting Komentar