Ito Wet Etching Process

Therefore wet etching is often used to pattern ITO films in the panel industry. The wet etching processes however might cause.

Dr Shabbir A Bashar S Ph D Thesis Chapter 5 Section 2

Of dry-chemical structuring by means of plasma etching wet-chemical etching methods have to be used for this purpose if necessary in combination with a subsequent fortifi cation by electroplating.

Ito wet etching process. The open circuit potentials included in the potential-pH diagrams for indium and tin in aqueous oxalic acid systems helped determine that ITO films. The etching process of ITO Indium Tin Oxide is used to form pixel electrodes of the liquid crystal displays. 132004 In this investigation the wet etching method was used to investigate the etching behavior of ITO films.

The X-ray photoelectron spectroscopy was used to study the surface. Partial Steps in Etching. The equivalent circuit parameters eg R ct C dl con.

XRR critical angle of the as-deposited 175 nm ITO film gives rise to a density of 6986 g expected value. Generally the aqua regia is used to etch the industrial ITO film with high throughput. A low-cost facile and template-free hydrothermal method adopted with a simplified architecture where etching process supports WO 3 to form an adhesive layer.

2082017 Herein we present for a first time an electrochromic film of WO 3 fabricated on an ITO by wet etching process using hydrochloric acid HCl. Wet etching is a simpler process than dry etching and has a high throughput and low cost. Etch rates for micromachining processing-part II.

Wetstation G and H. A wet etching process involves multiple chemical reactions that consume the original reactants and produce new reactants. This study examines how oxalic acid solutions affect indium tin oxide ITO etching.

Dielectric etching Organic removal Gold Plating Chemi-Mechanical Polishing CMP Example Wet Etching. Experimental results show that the etching rate of ITO films increased linearly with the concentration of C2O42-. As a novel approach to the in situ real-time investigation of an ITO electrode during the wet etching process step-excitation Fourier-transform electrochemical impedance spectroscopy FT-EIS was implemented.

When the wet etching time was increased from 05 to 3s the inverted conical structures were. It was reported that the ITO can be dissolved in etchants of halogen acids with a concentration of over 4 M 6 7 8. 2692018 The process was developed several years ago for touch panel industry which now is successfully replaced the wet etching process.

Wet Etch of ITO using Heated Diluted HCl Solution. In addition we noticed that a certain amount of ITO - varying from 05 m m to 15 m m was often etched away from underneath the photoresist. Wetstation C and D.

Silicon Etch using KOH TMAH 25 Photoresist Strip ITO Etch Aluminum Etch Pad Oxide Etch Oxide Nitride Etch Wafer Cleaning RCA Wafer Cleaning Piranha Clean Solvent Cleaning. When the wet etching time was increased from 05 to 3 s the inverted conical structures were completely formed on the GaN layer and. 12122017 The ITO film formed self-assembled inverted conical structures during the dipping etching process.

Etch rates for micromachining processing. As mentioned earlier the wet chemical etch process is highly dependent on a number of ambient conditions. 1 Diffusion of the liquid etchant to the structure that is to be removed.

And with long time developing and higher requirements from mobile phone industry this process is completed and used in many other applications mainly for developing or manufacturing sensor or circuits for OLED. Oxidation Dissolution Diff usion and Convection Oxidation The fi rst reaction step in wet-chemical etching is the oxidation of the medium to be etched. Sustainable valorization processes for selective recovery of pure copper nanopowder from Indium-Tin-Oxide ITO etching wastewater by various wet chemical reduction processes their chemistry has been investigated and compared.

For 25 min of etching time three. The wet etch process can be described by three basic steps. 642020 Selective Wet Etch of Cr over Ta using Cr Etchant.

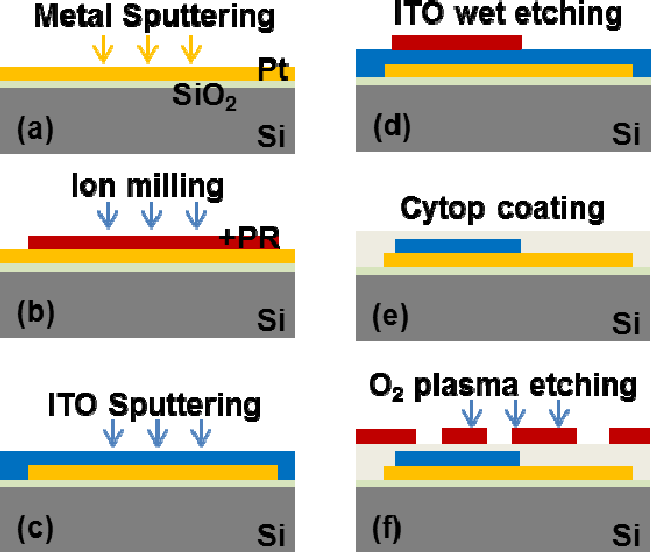

Wetstation E and F. For the ITO thin film during the wet etching process in oxalic acid at 60C. For patterning ITO films either dry etching or wet etch-ing can be adopted to produce the fine patterns.

Mixtures of NH 4 OH and H 2 O 2 etch copper as well. Please add any confirmed etches from this reference to the The Master Table of Wet Etching Include All Materials. Though the wet etching is the mainstream in ITO etching process now the dry etching is needed as making the pixel minute.

Wetstation A and B. After etching a film morphology mod-el that changes with etching time was obtained from the XRR pattern profile fit. And top-view SEM images of morphologies of ITO layers wet-etched in the FeCl 3HCl solution for 05 and 3s without covering with a photoresist mask.

The ITO film formed self-assembled inverted conical structures during the dipping etching process. This can be done either by complex formation or by oxidising components in the etching mixture for which hydrogen peroxide or nitric acid are often used. Copper Etching Copper is etched by also diluted nitric acid as well as saturated 30 Fe Cl 3 solution.

In severe cases thin traces of the photoresist remained on the substrate. 2 The reaction between the liquid etchant and the material being etched away. Patterning of thin films of ITO is usually done with lithography which includes an etching step that is mostly wet etching in industrial processesHydrochloric acid HCl and HCl with additional nitric acid HNO 3 or iron chloride FeCl 3 are often used as wet etchants at slightly elevated temperature for ITO films 2.

Etch Rate Of Ito Film At 40 50 And 60 C As A Function Of The Download Scientific Diagram

Figure 3 From Development Of Ito And Fet Based Cow Rumen Sensor For Long Term Ph Value Monitoring Semantic Scholar

Wet Etching Process Used To Roughen The Glass Surface Of Ito Glass Download Scientific Diagram

Hot Article Scanning Electrochemical Microscopy As An Etching Tool For Ito Patterning Journal Of Materials Chemistry Blog

Dr Shabbir A Bashar S Ph D Thesis Chapter 5 Section 2

Komentar

Posting Komentar