Ito Wet Etching

Wet etching is a simpler process than dry etching and has a high throughput and low cost. The open circuit potentials included in the potentialpH diagrams for indium and tin in aqueous oxalic acid systems helped determine that ITO films was dissolved by the formation of InC2O42.

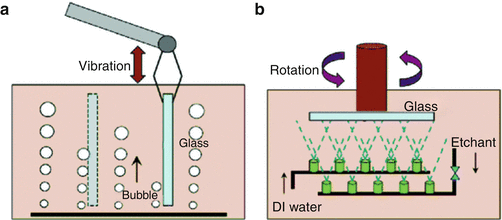

Wet Etching Process Used To Roughen The Glass Surface Of Ito Glass Download Scientific Diagram

It was found that ITO readily etches in HF solution HFH 2 O 2 10H 2 O and HCl solutions of various strengths.

Ito wet etching. This study examines how oxalic acid solutions affect indium tin oxide ITO etching. 132004 Either wet etching or dry etching was employed to fabricate a pattern of ITO films. HCl slow etch dilute or concentrated HNO 3 very slow etch dilute or concentrated H 2 SO 4 slow etch dilute or concentrated.

Experimental results show that the etching rate of ITO films increased linearly with the concentration of C2O42-. Concentrated HF typically 49 HF in water etches silicon dioxide too quickly for. However ITO cannot be etched in ammonia solutions 8NH 3 3H 2 O 2 400H 2 O.

The etch rates in HF were very high between 100sec to 150sec and often uncontrollable. Moreover HCl-based etchants such as hydrochloric acid HCl and HCl combined with nitric acid HNO 3 or ferric chloride FeCl 3 have widely been utilized in ITO etching1922. This study examines how oxalic acid solutions affect indium tin oxide ITO etching.

Will etch titanium as well. For isotropic wet etching a mixture of hydrofluoric acid nitric acid and acetic acid HNA is the most common etchant solvent for silicon. Oxidation Dissolution Diff usion and Convection Oxidation The fi rst reaction step in wet-chemical etching is the oxidation of the medium to be etched.

1121996 In contrast ITO residues were found after the etching of the films containing both amorphous and crystalline phases. Silicon dioxide or silicon nitride is usually used as a masking material against HNA. HClDI 12560ml150 ml putting onto 70 o C hot plate with a glass dish covering the top letting it heat up for 30 minutes the actual solution temperature.

5 Wet-etch ITO Film using HCl. In contrast to the dry etching the wet etching has relatively excellent throughput and is easy to transport the byproduct away from the ITO. Patent 4878993 teaches sputter etching of ITO films with a plasma consisting of dissociated argon.

This is attributed to the fact that the byproduct has a low vapor pressure. 2 NH 4 OH. H 2 O 2 thin films good for etching tungsten from stainless steel glass copper and ceramics.

On the other hand wet etching has several advantages including high throughput low cost and the use of a nonresidual etching source in the ITO films. Buffered oxide etch BOE also known as buffered HF or BHF is a wet etchant used in microfabricationIts primary use is in etching thin films of silicon dioxide SiO 2 or silicon nitride Si 3 N 4It is a mixture of a buffering agent such as ammonium fluoride NH 4 F and hydrofluoric acid HF. 3092014 Patterning of thin films of ITO is usually done by lithography which includes an etching step that is mostly wet etching since it requires less investment in equipment than others for instance plasma etching or laser ablation.

The wet etching processes however might cause. We have also developed a process for the fabrication of the ITO with a tapered edge profile. 1811994 While this method shows improved ITO patterns as compared with other wet etching methods the etching still proceeds isotropically resulting in patterns that are insufficiently fine and homogeneous for many purposes.

The dry etching nevertheless has a lower etching rate and it was difficult to pump out the byproduct. 22 صفوف 642020 Wet Etch of ITO using Heated Diluted HCl Solution. The open circuit potentials included in the potential-pH diagrams for indium and tin in aqueous oxalic acid systems helped determine that ITO films.

For patterning ITO films either dry etching or wet etch-ing can be adopted to produce the fine patterns. This can be done either by complex formation or by oxidising components in the etching mixture for which hydrogen peroxide or nitric acid are often used. Of dry-chemical structuring by means of plasma etching wet-chemical etching methods have to be used for this purpose if necessary in combination with a subsequent fortifi cation by electroplating.

Mixtures of NH 4 OH and H 2 O 2 etch copper as well. 522 Wet Chemical Etching. The taper angle can be controlled by varying the ratio of HNO3 to the HC1 in the etching solutions.

A Making the solution. Experimental results show that the etching rate of ITO films increased linearly with the concentration of C2O42-. 12122017 In the article we describe the etching mechanism of indiumtin oxide ITO film which was wet-etched using a solution of hydrochloric acid HCl and ferric chloride FeCl 3The etching mechanism is analyzed at various etching durations of ITO films by scanning electron microscopy SEM high-resolution transmission electron microscopy HR-TEM and selective area.

The concentrations of each etchant determines the etch rate. 1000ml K 3 FeCN 6. Copper Etching Copper is etched by also diluted nitric acid as well as saturated 30 Fe Cl 3 solution.

2742016 We typically etch ITO-coated glass with a mixture of hydrochloric acidwaternitric acid 421 by volume which is fairly fast at room temperature going through a few m in about 10 minutes and mask with a positive photoresist. Patterning of thin films of ITO is usually done with lithography which includes an etching step that is mostly wet etching in industrial processesHydrochloric acid HCl and HCl with additional nitric acid HNO 3 or iron chloride FeCl 3 are often used as wet etchants at slightly elevated temperature for ITO films 2. H 2 O rapid etch.

Partial Steps in Etching. Therefore wet etching is often used to pattern ITO films in the panel industry.

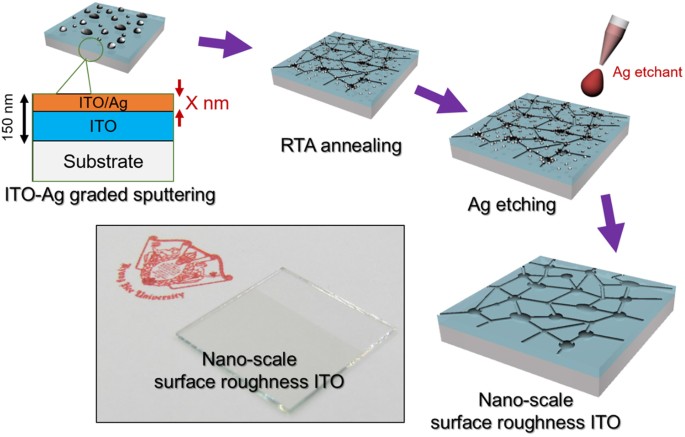

Tin Doped Indium Oxide Anodes With Artificially Controlled Nano Scale Roughness Using Segregated Ag Nanoparticles For Organic Solar Cells Scientific Reports

Dr Shabbir A Bashar S Ph D Thesis Chapter 5 Section 2

Https Www Mdpi Com 1996 1944 14 8 2025 Pdf

Figure 3 From Indium Tin Oxide Ito Transparent Mems Switches Semantic Scholar

Komentar

Posting Komentar