Lcd Ito Corrosion

In the fieldthe corrosive contaminants combined with moisture to form hydrochloric and sulfuric acid.

Pdf Recovery Of Indium Tin Oxide Ito And Glass Plate From Discarded Tft Lcd Panel Using An Electrochemical Method And Acid Treatments

Once corroded colouration and structural change of the ITO tracks is observed.

Lcd ito corrosion. This results in improved gray scale performance and therefore improved picture detail in those areas of the image that are primarily all dark or all bright. Depending on the oxygen content it can either be described as a ceramic or alloy. Indium tin oxide is typically encountered as an oxygen-saturated composition with a formulation of 74 In 18 O2 and 8 Sn by weight.

Contamination and moisture have proved to have the adverse effect of causing ITO corrosiondegradation. Indium Tin Oxide ITO in Touch Screens. 312008 Capillary action pulled the Isopropyl into the crevasse between the two glass plates of the LCD and dried directly on the ITO traces.

20122008 Results show that when ITO is subjected to harsh environment together with the presence of the electric field scratching acts as a tunnel for easy permeation of moisture and contaminants. TFT - LCD Display Mlanie Gaillet - Application Scientist - Thin Film Division Most displays in current use employ cathode ray tube CRT technology similar to that used in. ITO corrosion is a difficult problem in the LCD production.

Indium tin oxide is a ternary composition of indium tin and oxygen in varying proportions. The purpose of this paper is to determine if scratching the surface of ITO is a cause of ITO degradation.

Indium Tin Oxide or tin-doped indium oxide is particularly important to the worlds dominant smart phone and tablet manufacturers because of its unique material properties perfect for touch screen applications. ITO电极腐蚀 是LCD行业中普遍存在的难题 2 protection of ITO corrosion by TOP layer. The electrochemical corrosion behaviors of indium tin oxides ITO films were investigated by electrochemical methods in sodium hydroxide solutions.

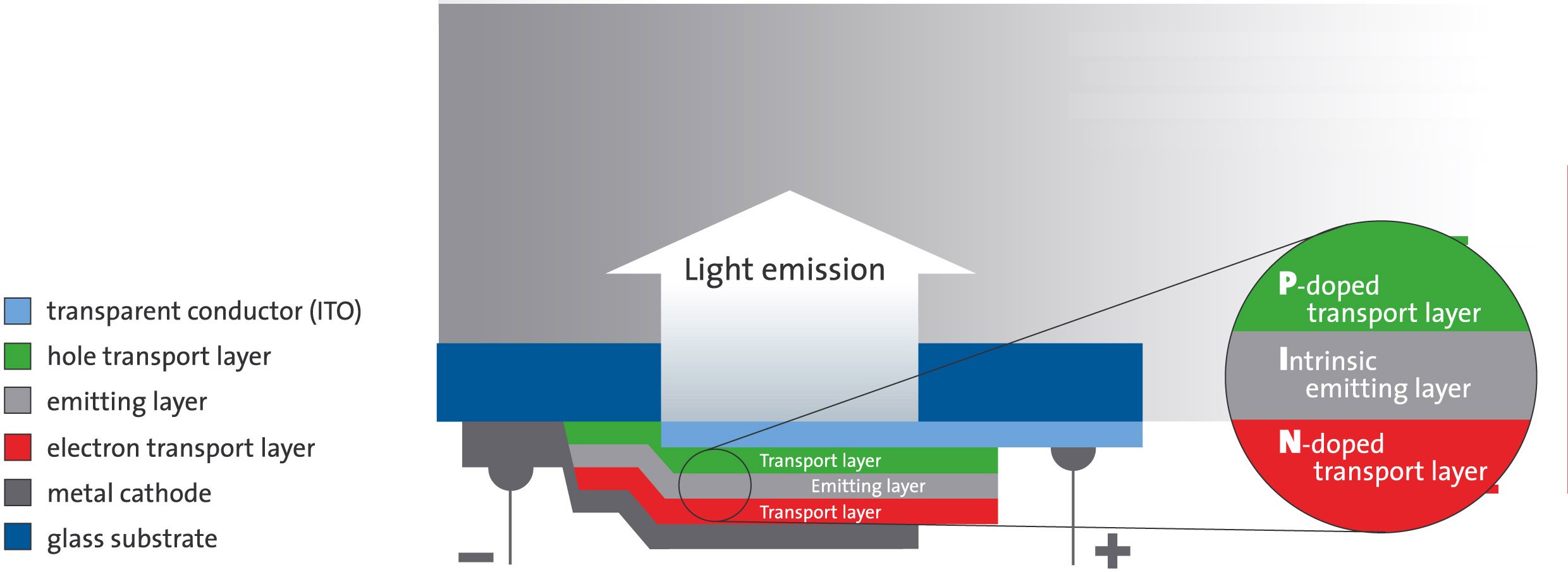

Oxygen-saturated compositions are so typical that unsaturated compositions are termed oxygen-deficient ITO. 20112017 ITO is a good material because it has a good response time to conduct electricity and an appropriate transparency for the emission of lightIt has been used as a conductive coating in photovoltaic cells solar cells since the light absorption layer has an electrode at both the front and rear to form a circuit and convert the light into electricityIt is also used in flat panel TVs where each pixel is turned ON or OFF by a pair of transparent electrodes ITO. 124 Corrosion Corrosion is the deterioration of a material resulting from chemical reaction with its environment - temperature pressure - concentration of the reactions and products - mechanical stress and erosion Can be regarded as reverse extractive metallurgy Metal oxide silicate carbonate Metal Metallurgy reduction Corrosion.

1272013 Great explanation of basic touch screen technology. Using Arrhenius model and Eyring modelthe reliability properties of LCD electrode corrosion were studied by corrosion acceleration experiments of LCD electrode with thermal stress humidity stressand a typical verifiable LCD life was derivedThe results showed that corrosion velocity of LCD electrode was index function of thermal and humidityThat meansLCD products pass the. A layer of material such as crystalline indium tin oxide ITO is formed on top of a substrate by heating the material to a high temperature while a temperature increase of the substrate is limited such that the temperature of the substrate does not exceed a.

The presence of Cl -reacts with moisture and forms HCl that etch the ITO. 2692011 ITO Corrosion Prevention Actionsmoto - ITO Corrosion Prevention Actions Content 1 Implement E. Transmittance spectra scanning electron microscopy SEM and X-ray diffraction XRD analysis.

Covered with an ITO layer and a polymer layer. Indium tin oxide ITO has been widely used in liquid crystal displays LCD. This can be done by dissolving color filter CF layer which is located between ITO layer and glass substrate.

Cyclic voltammetries of ITO films at both anodic and cathodic polarization were carried out. In this study indium-tin-oxide ITO nanoparticles were simply recovered from the thin film transistor-liquid crystal display TFT-LCD panel scraps by means of lift-off method. 182017 Most of the todays LCD displays support a minimum of 256 levels of brightness per pixel though high-end LCD panels used in LCD signage can support up to 1024 different levels of brightness.

ITO is a semi-transparent conducting material which.

Tf 4200eb 452 Blue Glue Sealant Adhesives Glue For Lcd Led Display Backlight Module Ito Insulating Protection Dhl Not Shipping Cpr018030103 162 00 Full Cell Phone Spare Parts Lcd Refurbishment Machines Electronparts

Pdf Recovery Of Indium Tin Oxide Ito And Glass Plate From Discarded Tft Lcd Panel Using An Electrochemical Method And Acid Treatments

About This Guide This Document Is Intended To Provide Guidance And Cautions Related To Integrating An Analog Resistive Touch Screen Into An Enclosure The Topics And Suggestions Contained Within This Document Are Taken From Years Of Experience

Pdf Recovery Of Indium Tin Oxide Ito And Glass Plate From Discarded Tft Lcd Panel Using An Electrochemical Method And Acid Treatments

What Is Indium Tin Oxide Metallurgy For Dummies

Komentar

Posting Komentar