Ito Surface Resistance

Giant unilamellar vesicle GUVs were produced on ITO coated glass slides by drying droplets of the FhuA proteoliposomes. ITO pattern hiding through index matching.

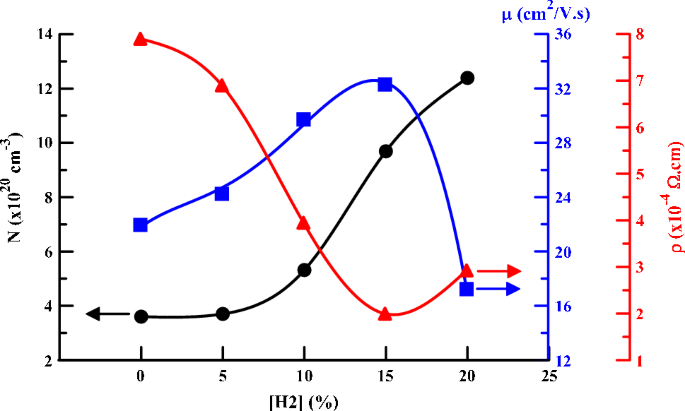

Electrical Conductivity Enhancement Of Indium Tin Oxide Ito Thin Films Reactively Sputtered In A Hydrogen Plasma Springerlink

125 mm x 125 mm x 07 mm.

Ito surface resistance. Due to their low electrical surface resistivities many of our ITO coatings are an ideal solution for constructing EM protection windows that must transmit. The primary reference for this measurement has been ASTM D-257 Standard Test Methods for D-C Resistance or Conductance of Insulating Materials. Indium tin oxide ITO is widely used as a substrate for fabricating chips because of its optical transparency favorable chemical stability and high electrical conductivity.

The surface resistance of the ITO layer is no more than 400 omegasquare. To 100 ohms per square. Visible light transmission was 85.

The surface resistivity of a fully oxidized ITO-coating depends on the film thickness and vice versa. Patterned and Printed Widths. The specified surface resistance of the ITO coated conductive glass slides is between 10 ohmssq and 100 ohmssq.

In this way no adhesive agents are. Cockpit Displays for Avionics. 75mil optically clear PET films.

Certified Area 30 mm diameter in the center of the plate Sheet Resistance Uniformity in the Certified Area. The copper lead layer is arranged on the ITO. Used primarily for LCD displays our transparent conductive coatings can be fully customized to exact specifications with the capability of achieving less than 035 specular reflectance and sheet resistance as low as 4 to 3000 ohms per square.

PRODUCT DESCRIPTION The ITO Sheet Resistance Standard consists of a glass substrate with a thin film of indium tin oxide sputtered on it. 60 100 200 270. 50 125 175.

Hence it isnt possible to make a specification for. Oct 01 2013 Nominal resistance of ITO was 4060 Ωsquare and its nominal thickness was 125 nm likewise nominal thickness of PET was 125 m. The sheet resistance of ITO after bending to a radius of 25 mm was investigated for its use for flexible optical devices.

15 1s Certified Expanded Uncertainty. These ITOPET sheets were cut to samples. 125 mm x 125 mm ITO Sheet Resistance Standard.

ASTM D-257 measures the resistive or conductive properties of insulative. The specified surface resistivity of the ITO coated glass sheet is in the range of 10 ohmssq. ITO Sheet Resistance Standards ITOSRS Product Specifications.

Jun 01 1996 ASTM D-257 Surface Resistivity. Dec 01 2007 Alkali cleaned and SAM modified ITO gave a lower contact resistance of about 634. It is commonly used to characterize materials made by semiconductor doping metal deposition resistive paste printing and glass coatingExamples of these processes are.

Nominal Sheet Resistance Values. 10 3 Ω cm 2 respectively than. Mar 15 2020 The sheet resistance of ITO coatings varies with the coatings thickness the greater the thickness the lower the resulting sheet resistance we therefore produce these coatings in varying thicknesses to cater for diverse.

10 4 Ω cm 2 and 188. The entire surface of the glass substrate is coated with the ITO film but only the center portion of the substrate 30 mm in diameter is certified. Use of ITO coated conductive glass.

The transmittance of the Indium Tin Oxide ITO glass coverslips at 550nm are greater than 85. Fine ITO patterned features. The transmittance factor of ITO coated glass coverslips at 550 nm is greater than 85 offering optimum storage.

Doped semiconductor regions eg silicon or polysilicon and the resistors that are screen printed onto the substrates. 188m 2 5 7. The ITO film or layer thickness is in the.

Sheet resistance is a measure of resistance of thin films that are nominally uniform in thickness. For many years surface-resistivity measurements have been used to classify ESD-controlled packaging materials. The first sets of dimensions were used to study the breaking mechanism of ITO.

Our ITO Coatings are used in a range of applications including. Specialty protection films adhesive and hard coats available as custom options. However the wettability of ITO surface is neutral the contact angle was approximately 90 or hydrophilic.

Base Film Thickness. 90 Ω Material 90 In 2 O 310 SnO 2.

Oxygen Plasma Treatment Effects Of Indium Tin Oxide In Organic Light Emitting Devices Sciencedirect

Pdf A Study Of Low Temperature Crystallization Of Amorphous Thin Film Indium Tin Oxide

Pdf Work Function Of Indium Tin Oxide Transparent Conductor Measured By Photoelectron Spectroscopy

Low Resistance Highly Transparent And Thermally Stable Ti Ito Ohmic Contacts To N Gan Journal Of Vacuum Science Technology B Microelectronics And Nanometer Structures Processing Measurement And Phenomena Vol 27 No 3

A Transmission Spectra Of Ito Thin Films With Various Thickness 0 5 Download Scientific Diagram

Komentar

Posting Komentar