Ito Glass Cleaning Process

Chemically reactive process gases air oxygen react with hydrocarbon monolayers to form gaseous products that are swept away by the continuous gas flow in the plasma cleaner chamber. Sonication with DI water for 10min.

Ito Obtained By Spray Pyrolysis And Coating On Glass Substrate

Important information on proper glass cleaning procedures including the following.

Ito glass cleaning process. A pattern is etched away from the Indium Tim Oxide. All glassware should be wiped from outside with moist methanol or water tissue paper so that if there are stains inside the glass they are visible and can be cleaned again. To save this half hour I will simply show you the before and after shot of the taped glass and then the diced glass and possibly demonstrate a single cut just so that you believe me that this is possible.

The result is a transparent tin oxide coating which is very adherent and electrically conductive. ITO etching single surface etching double surface etch and metal etching. The samples can be placed in UV-ozone UVO-Cleaner to remove any residual organic.

We for more detailsRead complete Article here. Techinstro advised to use the following procedure for ITO layer cleaning. Using a cotton bud firmly wipe away the etched area of.

Plus FTO glass can be laser scribed patterned. 9212 OLED Fabrication Procedure The ITO glass plate is pretreated at a pressure of 80 milli torr with the flow of argon and oxygen at a rate of 50 SCCM standard cubic meter for 420 seconds. Rinse thoroughly in DI water and blow dry with nitrogen.

Start cleaning from bottom-up or top-down. 12102013 1 cleaning in a deionized water detergent Hellmanex mixture in ultrasonic bath 60 min 2 30min in deionized water in ultrasonic bath 3. 1222019 The patterns on the sensor glass set the characteristic of the touch panel.

This pretreated glass plate is placed on a holder in the glove box and later transferred to the plasma chamber for plasma treatment. Rinse with DI water. Solvents can clean oils and organic residues which appear on glass surfaces.

The patterning process of the ITO substrate can be very accurate. The etching process includes. ITO Glass can be patterned.

Best time of day for cleaning glass Avoid glass to metal contact What type of detergent to use Razor scraping is quicker but it causes. This means that a simple cleaning routine which can take as little as 20 minutes can be used to provide a pristine ITO surface without the need for plasma ashing of the substrate. 8252009 Otherwise use RO water to clean the water based chemicals.

Coat the FTO glass substrate in a layer of Zinc Powder. Sonication of the sample plays an important role in the cleaning process of substrate. Place an etch resistant tape onto the FTO glass substrate.

Sonication of the sample plays an important role in the cleaning process of the substrate. In addition the accuracy of the laser printing Excimer VUV cleaning system Photo-alignment system and other process systems can affect the quality. Plasma cleaning removes organics contamination through chemical reaction or physical ablation of hydrocarbons on treated surfaces.

Cover the remaining Zinc Powder with the 2M HCl solution and wait for the reaction to finish. 492014 In this tutorial you learn how to clean ITO coated glass substrate. Use a lint-free wipe and cotton swab to gently rub the surface clean of dirt and residues.

Deconex or FPD detergent Alconox. Soaked under the detergent at 60C for 10 min. Patterning is suitable for large and small production requirements.

The procedure is to apply the backing tape program the saw perform alignment to our ITO patterns and then press GO. The first step is to load the substrates into the cleaning rack such that they all have the same orientation. Initially take acetone and mixed with the substrate which is to be cleaned and sonicate approximately for 20 minute.

111999 ITO glasses can be cleaned by sonicating for 30 minutes first in acetone then in isopropyl alcohol IPA. 852008 A fairly common practice in making glass bottles aircraft windshields and other glass in which the end use requires abrasion resistance is to spray the hot glass with a tin compound such as Tin IV Chloride. Cleaning Initial Glass Substrates ITO Coated Scribe backside.

Prepare a bath of soapy water. 11202017 Absorption occurs when the photon energy corresponds to what is necessary to let the electron in an excited stateIn a metallic conductive material there is a good passing of electronics but unfortunately all the metals are highly opaqueManufacturing process of ITO GlassTo produce the thin films of ITO glass it is common to use sputtering techniques with radio frequency. 182 M DI water.

TECHINSTRO ADVISED TO USE THE FOLLOWING PROCEDURE FOR ITO LAYER CLEANING. Then take out. Following is the cleaning method for ITO products.

Soap clean SOAPCLEAN Most slides and glass surfaces can be effectively cleaned with soapy water. ITO is swabbed under a diluted detergent eg. Advice for cleaning stucco and concrete slurry spots from glass.

Contrad 70 60 min 45 C. 112016 Our ITO glass supplier Xinyan Technology wwwxinyanhk suggest the below cleaning procedures. This should be adequate for your needs.

Chromerge should be used only if it is brown not green and substrates should not be dipped in it for a period more than one hour because. Initially take acetone and mixed with the substrate which is to be cleaned and sonicate approximately for 20 minutes.

China Dongguan Factory 5 100ohm Patterned Ito Glass 1 1mm Indium Tin Oxide Glass Factory And Suppliers Saida

What Is The Best Way To Clean Ito Coated Glass Substrate

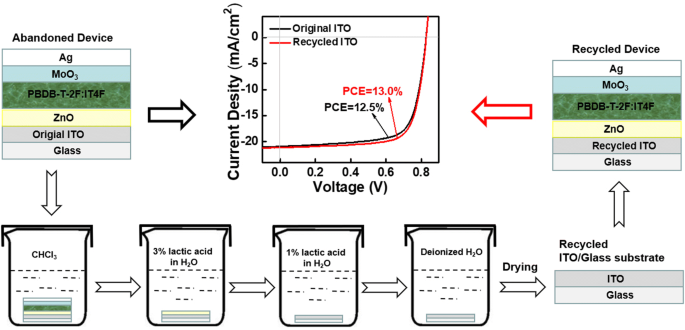

Recycled Indium Tin Oxide Transparent Conductive Electrode For Polymer Solar Cells Springerlink

Schematic Illustration For Fabrication Of Ito Ag Superhydrophobic Sers Download Scientific Diagram

Sem Images Of Aunps Deposited On Ito Glass After Annealing At 400 C Download Scientific Diagram

Komentar

Posting Komentar