Ito Thin Films

10 6 torr prior to sputter and then backfilled with argon gas and sputtering source target that was 3 in. The surface and cross-sectional images indicate that both the grain size and densification of the ITO and In₂O₃ films.

High Temperature Optical Properties Of Indium Tin Oxide Thin Films Scientific Reports

01-04-2021 ITO thin films can be prepared via several methods such as the sol-gel technique 419 pulsed laser deposition PLD 220 pulsed DC sputtering radio frequency RF sputtering 121621 RF-superimposed DC magnetron sputtering spray chemical vapor deposition laser sintering and vacuum evaporation.

Ito thin films. Glass additives were added to improve the sintering process and to increase the density of the In₂O₃ITO films. It is observed that amorphous layer with thickness of 80 nm was formed at the interface on the polymer substrate and polycrystalline phase evolved above. 07-10-2015 The ITO thin films were synthesized on soda lime glass substrates by an RF sputtering system which is shown in Fig.

A sputtering chamber that was evacuated to less than 94. Benefits Indium Tin Oxide ITO or tin-doped indium oxide is a mixture of indiumIII oxide In 2 O 3 and tinIV oxide SnO 2 typically 90 In 2 O 3 10 SnO 2 by weight. Growth and Characterization of Ito Thin Film by Magnetron Sputtering Paperback.

01-11-2000 Transparent conducting indium tin oxide ITO thin films 40870 nm were grown by pulsed laser deposition on amorphous substrates and the structural electrical and optical properties of these fi. 08-11-2016 3 ITO thin film preparation method and technology. An In₂O₃ITO thin film thermocouple was prepared via screen printing.

The sol transformed into an amorphous gel during heating which dec. 1An RF sputtering system includes. ITO film can be used to prepare a lot of film forming technology such as magnetron sputtering deposition vacuum evaporation deposition and sol gel -Gel Sol etc.

In this study Indium Tin Oxide ITO thin films were grown by both DC. ITO thin films can be prepared by a variety of methods including electron beam evaporation Reference George and Menon 1 sputtering Reference Gorjanc Lemig Py and Roth 2 chemical vapor. A stable sol was prepared from indium nitrate and tin acetate precursors together with acetic acid and ethylene glycol.

27-07-2020 Indium tin oxide ITO is one of the most widely used transparent conductors in optoelectronic device applications. 27-05-2020 As ITO plastic film coatings can withstand harsh environments and temperatures ITO thin film strain gauges can be used in extreme environments such as gas turbines and the engines of jets and rockets. Indium tin oxide ITO is a material belonging to the group of transparent conductive oxides which are widely used in many fields of technology including optoelectronics and photovoltaics.

It is transparent and colorless when deposited as a thin film at thicknesses of 1000-3000 angstroms. Another similar use of ITO plastic films within the aerospace industry is that of ITO films use in defrosting an aircrafts windshield. 31 magnetron sputtering deposition.

Based on these results we suggest that the growth of ITO thin films can be described by the combination of the Edwards-Wilkinson equation and Mullins diffu-sion equation. However the properties of ITO thin films depend on many factors. Fabrication of Nanopillar Crystalline ITO Thin Films with High Transmittance and IR Reflectance by RF Magnetron Sputtering.

Diameter by 90 In 2 O 3 and 10 SnO 2 9999. We investigated the optical properties of ITO thin films at high temperatures up. For ITO thin films were determined to be 073 001 and 0078 respectively.

3 the micrograph of the cross-section of 150 nm thick film is shown. These transparent-yet-conductive thin films are now crucial components of the high-resolution liquid crystal displays and touch sensor functions in the smartphones people use in their daily lives. 31-01-2011 Indium tin oxide ITO has been widely used as a transparent conductor in optoelectronic devices such as light emitting diodes solar cells liquid crystal displayers etc.

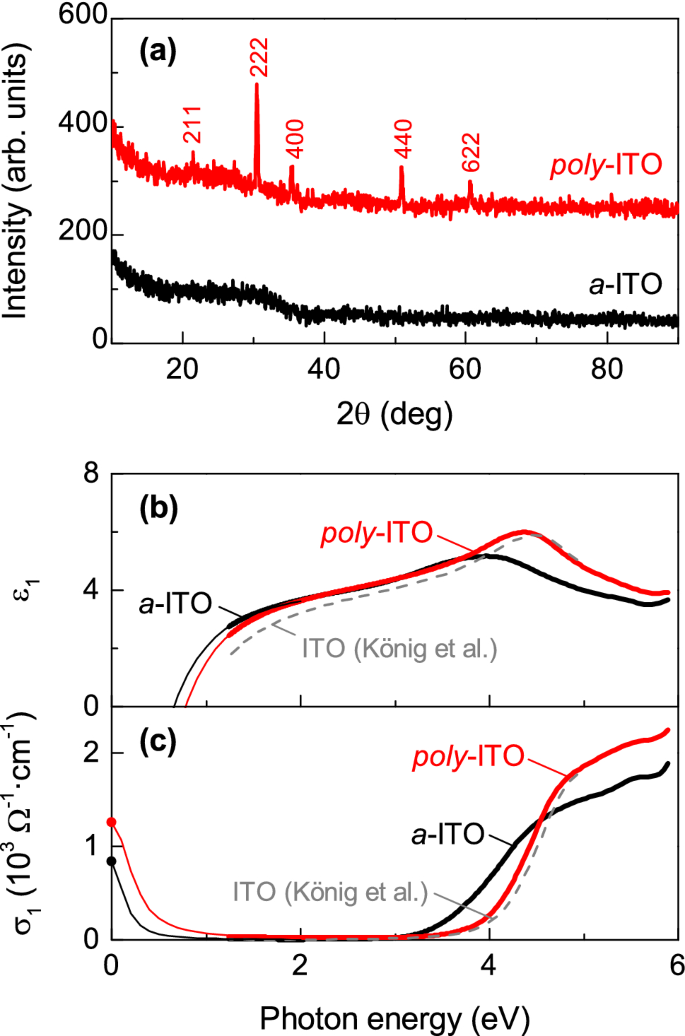

ITO films types of transparent films Geomatec began technological development of in the 1970s. An environmentally friendly aqueous solgel process has been developed to fabricate thin films of indium tin oxide ITO. High quality ITO thin films grown by dc and RF sputtering without oxygen Ocal Tuna1 Yusuf Selamet1 Gulnur Aygun1 and Lutfi Ozyuzer123 1 Department of Physics Izmir Institute of Technology TR-35430 Urla Izmir Turkey 2 Teknoma Technological Materials Ltd IYTE Campus TR-35430 Urla Izmir Turkey E-mail.

15-11-2006 In order to investigate the microstructure of ITO thin film the cross-section of the film was observed with scanning electron microscopy.

A Refractive Index And B Extinction Coefficient Of Ito Films Download Scientific Diagram

Optical Band Gap And Transmittance Spectra Of The Ito Thin Film Download Scientific Diagram

Indium Tin Oxide Ito In203 Sn02 Sputtering Targets Size 2 Thickness 0 125 Purity 99 99 Nanografi

Low Resistance Highly Transparent And Thermally Stable Ti Ito Ohmic Contacts To N Gan Journal Of Vacuum Science Technology B Microelectronics And Nanometer Structures Processing Measurement And Phenomena Vol 27 No 3

Ion Beam Sputtering Beams Physical Vapor Deposition Thin Film

Komentar

Posting Komentar