Ito Dry Etching Recipe

45 sec for full etching of DUV-42P same as for AR6. 3a the PR has withstood the ICP dry etch.

Materials Free Full Text One Step Etching Characteristics Of Ito Ag Ito Multilayered Electrode In High Density And High Electron Temperature Plasma Html

US5171401A US07533232 US53323290A US5171401A US 5171401 A US5171401 A US 5171401A US 53323290 A US53323290 A US 53323290A US 5171401 A US5171401 A US 5171401A Authority US United States Prior art keywords ito plasma etching argon tin oxide Prior art date 1990-06-04 Legal status The legal status is an assumption and is not a legal conclusion.

Ito dry etching recipe. Organic gases that contain CH 4 form polymeric hydrocarbon films which are easily deposited on etched surfaces and impede the etching process. RIE 2 MRC RIE 3 MRC RIE 5 PlasmaTherm DSEIII PlasmaTherm SLR Fluorine ICP PlasmaTherm ICP Etch 1 Panasonic 1 ICP Etch 2 Panasonic 2 ICP-Etch Unaxis VLR Ashers Technics PEII Plasma Clean Gasonics 2000 Plasma Clean YES EcoClean UV Ozone Reactor. As seen in Fig.

Plasma processes for dry etching of transparent materials. The maximum etch rate of ITO thin film was 1300 nmmin upon the addition of Ar 6 sccm to the Cl2BCl3 416 sccm plasma which was higher than that with He or N2 added to the plasma. Develop the film remove excess with water.

Works very well for photoresist stripping. The etching rates of ITO films depend strongly on power density gas pressure the composition of reactive gases and the total flow rate of etchants. The reaction dead time is characteristic of the ITO dryetching process but the reaction is relatively simple.

Itoの エッチング方法としてはhihbrhc1 FeCl3等 の溶液を用いたウエットエッチングとハ ロゲ ンガス系および有機ガス系を用いたドライエッチングが. The preparation method of the etching liquid comprises the steps that the rotating speed of a stirrer of a dosing tank is kept at normal temperature and. Using AFM the surface roughness of the ITO deposited on polycarbonate was investigated after the dry etching of ITO in MICP using various ArCH 4 gas combinations and the results are shown in Fig.

ICP 75W RF 75W. The mechanism of ITO etching is somewhat complicated but typically centers around hydrochloric acid usually in combination with an oxidizing agent. No helium cooling Run in manual mode.

Use some of this 32 HCl to etch the ITO. Prior to the ICP etch PR was hardened and reflowed by heating it on a hot plate at 130 C for 5 min. The etching liquid is prepared from phosphoric acid acetic acid nitric acid additives surfactants and pure water.

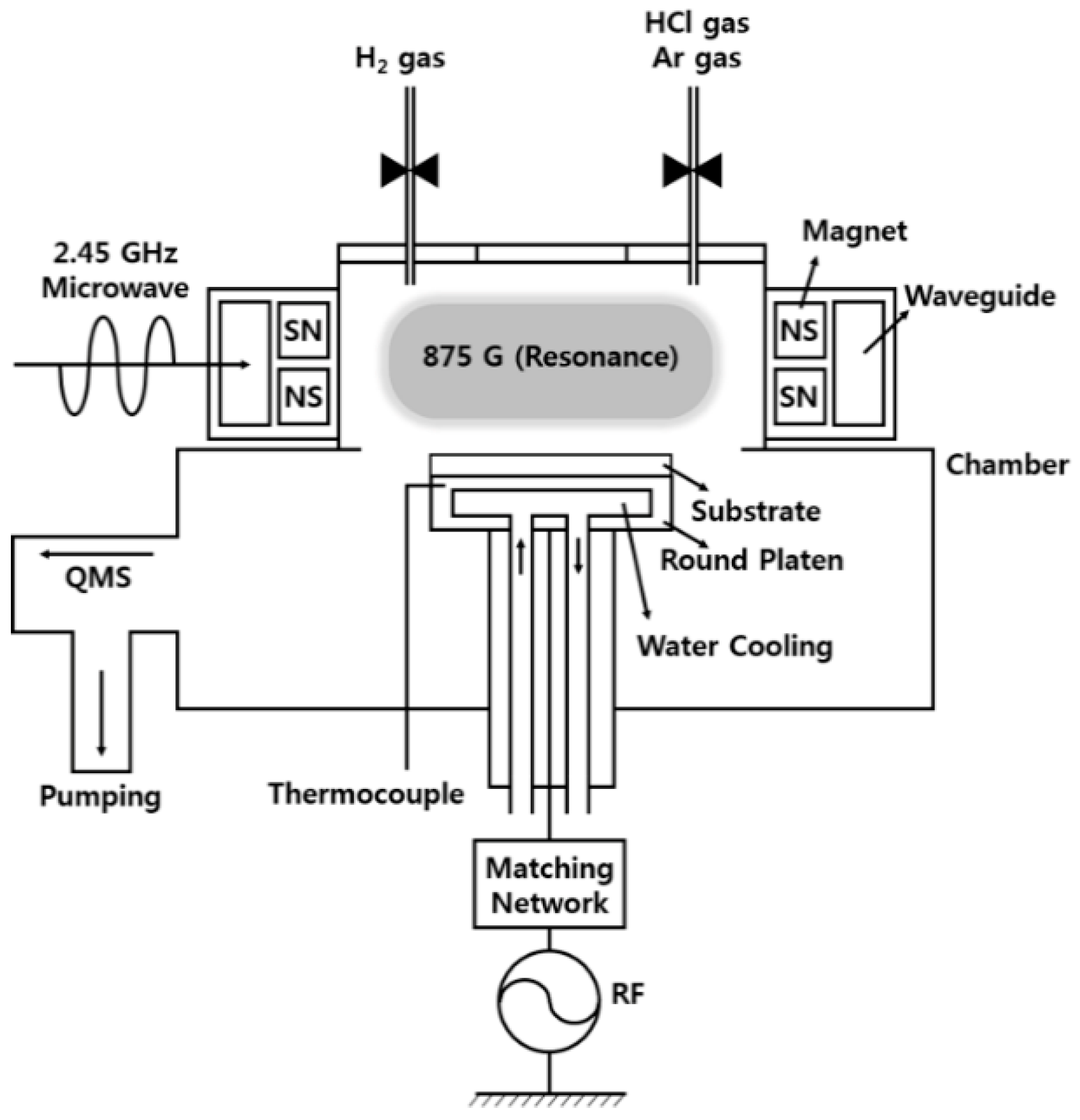

Plasma Activation EVG 810 XeF2 Etch. Gale Fundamentals of Micromachining BIOEN 6421 EL EN 5221 and 6221 ME EN 5960 and 6960 Etching Issues - Anisotropy Isotropic etchants etch at the same rate in every direction Isotropic mask An-isotropic Etching Issues - Selectivity Selectivity is the ratio of the etch rate of the target material being etched to. In this study the dry etching of ITO layers deposited on glass substrates was investigated in a magnetic pole enhanced inductively coupled plasma MaPE-ICP source using mainly argon methane and.

16092019 GaAsAlGaAs Etch Recipes - BCl3-SiCl4. 15032006 Different gas mixtures were used to etch the ITO layers including argon oxygen and acetone CH 4 H 2 or SiCl 4 CF 4 CH 4 mixtures by a reactive ion etching process. Basic recipes for etching photoresist and Bottom Anti-Reflection Coating BARC underlayers are as follows.

18062012 Abstract Based on HI gasplasma etching highdensity plasmaassisted RIE the activation energy for an ITO dryetching reaction was obtained. GaN Etching RIE 5 GaN Etch Recipes - Cl2-BCl3-Ar. O2 20sccm Pressure 10mT RF 100W Time 40 sec.

The invention discloses ITO-Ag-ITO etching liquid for an AM-OLED display screen and a preparation method. A few specific ITO etch bath recipes. However this technique needs cumbersome optimisation of the various constituent gas partial pressures to ensure that no carbon debris is left on the surface.

28012014 Indium-tin oxide ITO films coated on glass have been etched by reactive ion etching RIE with a gas mixture of Ar and Cl 2. 500 W of inductive power 200 V of bias voltage and 067 Pa of operation pressure. The etching of ITO thin films using a fluorine-based gas such as in CF 4 plasma methods has the disadvantage of inducing contamination due to polymerization.

The etch selectivity of ITO to SiO 2 and Si 3 N 4 was over 10. Recently many studies on the dry etching of ITO thin films have been reported. No need to pumppurge can etch right away.

The ion bombardment by Ar sputtering. Methane 2 acetone ethanol 3 methanol 4 and more recently hydrogen bromide-based plasmas have been used to etch ITO but in most cases the application was not for flat dis-. 27042016 Use some of this UV-cure dry film a transparency and a fluorescent light fixture placed very close to it for a while to cure it not sure if enough UV there at the right wavelengthI may get one of those UV LED nail spa cure things.

28012014 A very high etching rate of ITO films of over 200 nmmin was obtained at 100 CH 4 while the high etching rate of 100 nmmin was achieved even at 100 H 2 with the moderate dc self-bias voltage of 300 V. 2018-2019 DemisBrianT UV6-08 Etching. Dry etching of ITO using a gas mixture of acetone argon and oxygen - essentially a hydrocarbon etch with acetone being the source of reactive organic radicals in the plasma discharge - has also been reported.

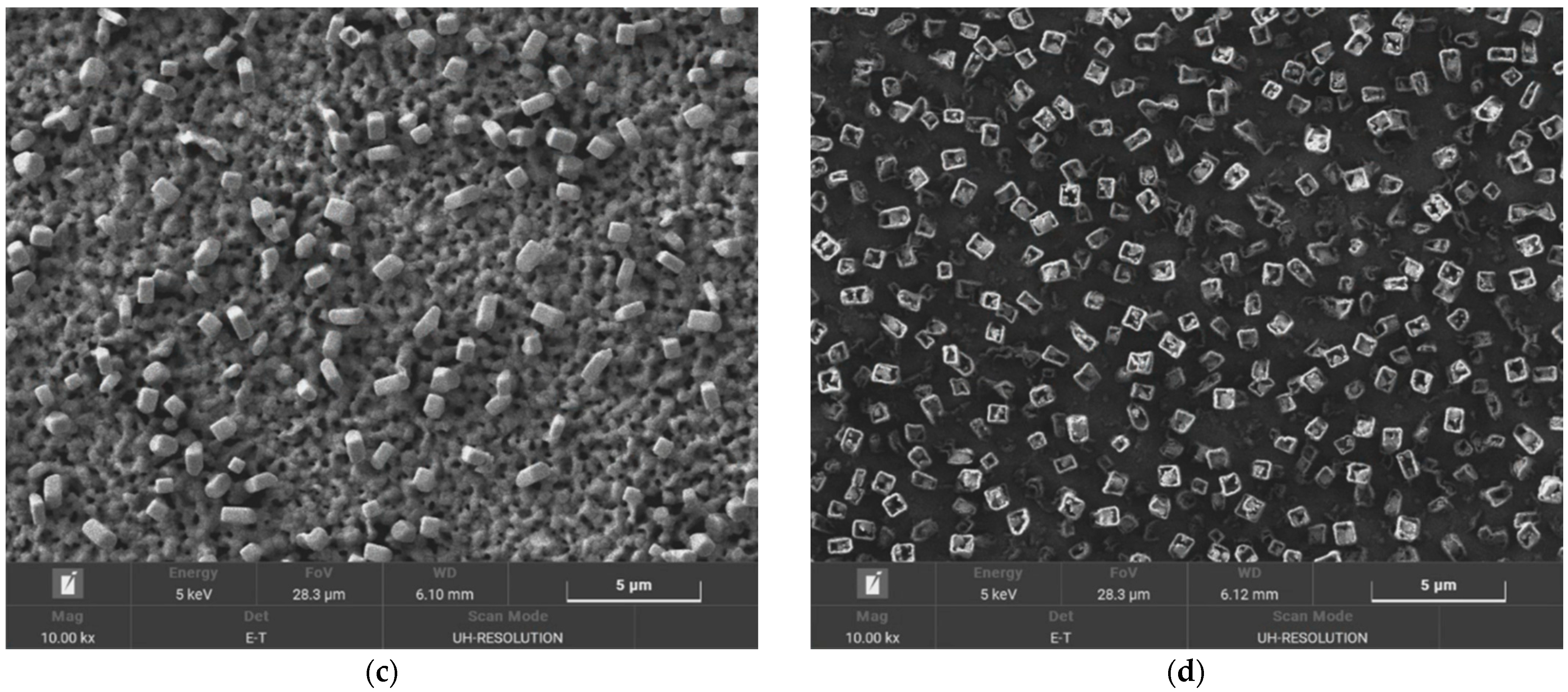

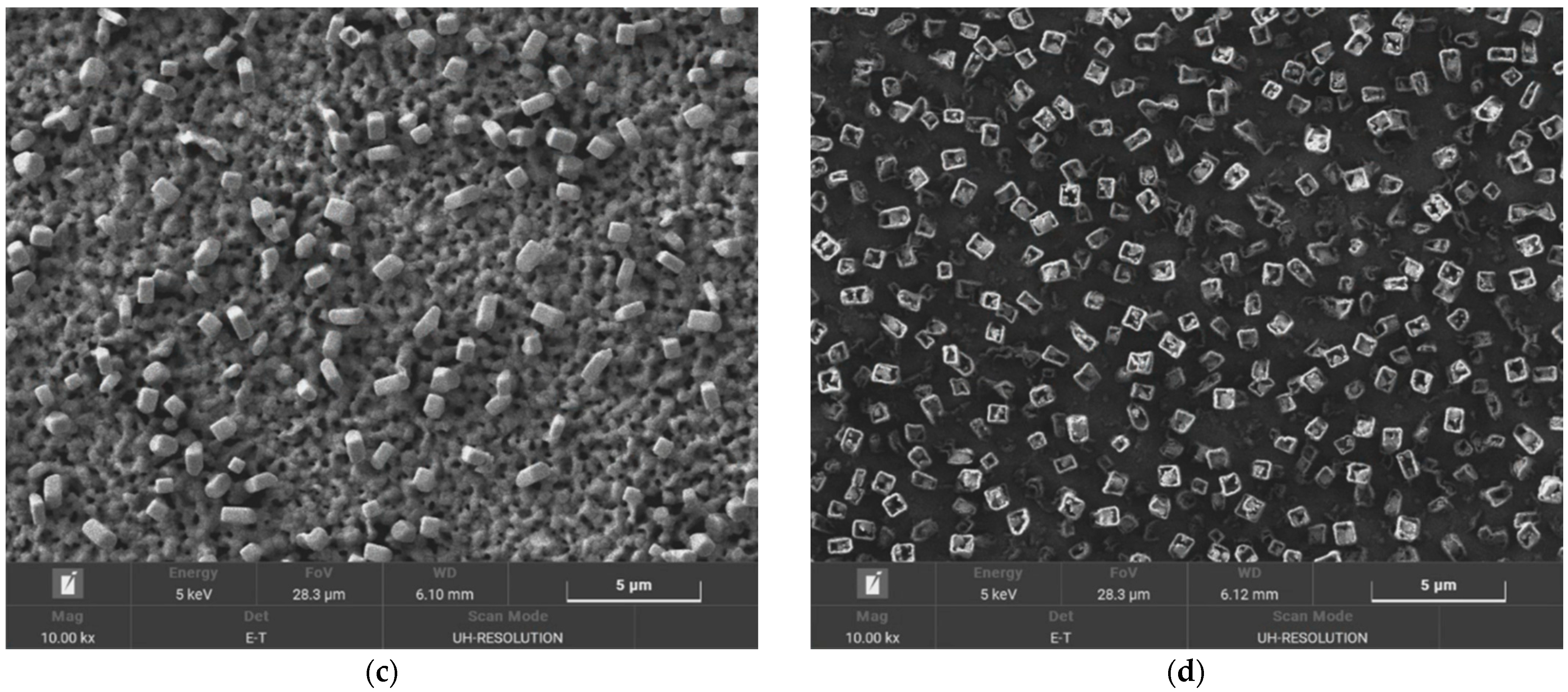

3a and 3b show SEM images of an ITO pillar on Si sub-strate etched under 200 W ICP power 150 W RIE power with 10 sccm of CH 4 and 50 sccm of H 2 at 10 mTorr and 50 C. In this study we investigated the etching characteristics of ITO thin films and the effects of inert gases added to Cl 2 BCl3 inductivity coupled plasma. Many recipes call for heating of the etchant to 40-50 C to increase etch rates etch rate is exponential with temperature.

O2 40 sccm 05 Pa. The value was calculated 3540 kJmol for 20 sec from the reaction starting time. Photoresist and ARC etching.

04022021 RIE Etching ICP Etching Oxygen Plasma Systems Other Dry Etchers. The dependences of etching rate on substrate temperature and self-bias dc voltage suggest that the high-flux ion bombardment given by the inductive rf plasma enhances the etching of ITO.

Dr Shabbir A Bashar S Ph D Thesis Chapter 5 Section 2

Dr Shabbir A Bashar S Ph D Thesis Chapter 5 Section 2

Pdf Dry Etching Of Ito By Magnetic Pole Enhanced Inductively Coupled Plasma For Display And Biosensing Devices

Dr Shabbir A Bashar S Ph D Thesis Chapter 5 Section 2

Materials Free Full Text One Step Etching Characteristics Of Ito Ag Ito Multilayered Electrode In High Density And High Electron Temperature Plasma Html

Komentar

Posting Komentar